Scaffolding pipe Thread Rolling Machine is a kind of multi-function cold extrusion forming machine, and the spinning function can process the thread, straight grain and twill rolling in the cold state within the range of the rolling pressure.Rolling of straight teeth, oblique teeth and helical spline gear;Straightening, reducing, rolling and all kinds of forming rolling.The machine has a safe and reliable electrical - hydraulic execution and control system that allows each working cycle to be selected in three ways: manual, semi-automatic and automatic.The cold rolling process of rolling wire is an advanced non-cutting process, which can effectively improve the internal and surface quality of the workpiece. The radial compressive stress generated during processing can significantly improve the fatigue strength and torsion strength of the workpiece. It is an ideal process with high efficiency, energy saving and low consumption.

Technical parameter for scaffolding pipe thread rolling machine:

Items ZP28-65

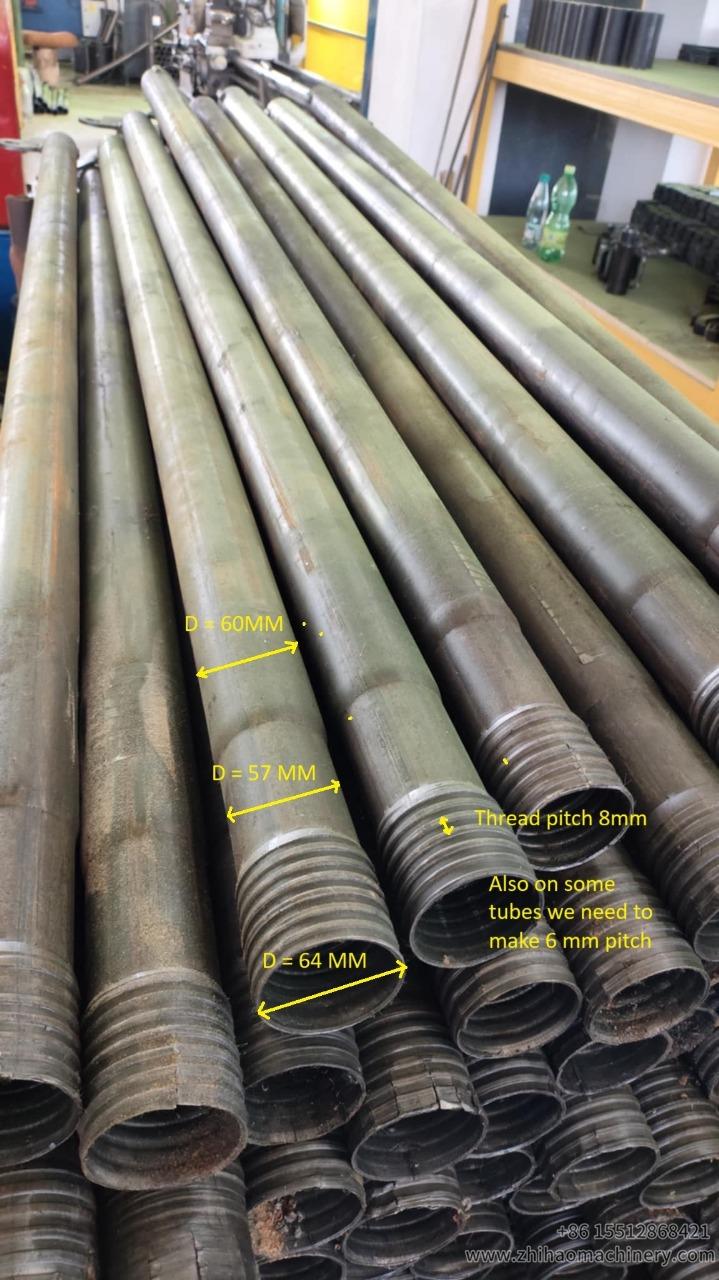

Rolling thread range Diameter 80mm

Max thread pitch 8mm

Spindle angle ±6°

Max rolling pressure 250kn

Spindle RPM 22/28/35/45/56/70rpm

Roller size range Outside diameter 180mm

Hole 54mm

Max width 100mm

Rolling time 0.1-99.9s

Rest time 0.1-99.9ss

Spindle drive power 11kw

Hydraulic transmission power 3.0kw

Dimension 1800*2200*1800mm

Weight 3100kg

If have any interesting for automatic hydraulic thread rolling machine, pls contact us freely.

Mob/whatsapp +8615512868421

Email: sales@zhihaomachinery.com

Contact: kitty

Phone: +86 15512868421

E-mail: sales@zhihaomachinery.com

Whatsapp:+86 15512868421

Add: XingWan Industrial Zone, Xingtai CIty, Hebei province, China.